My first day in the cellar at Gabrielskloof was a busy one. This cellar is shared by Peter-Allan Finlayson (who makes Crystallum wines, and also Gabrielskloof, his wife Nicolene’s family winery), John Seccombe (Thorne and Daughters), and Marelise Niemann (Momento), and this means there’s plenty going on.

The day started with some pressing of Chenin Blanc. This was from the Paardeberg, and it was John’s. The season there has been very dry, but the grapes looked lovely: small berries, with good acidity and nice flavour. They had been picked in 20 kg crates, and so we had to fill the press by hand. This is quite hard work.

There were four tons of grapes, which means two press loads. The press in question is a vintage item. It’s a Vaslin fixed cage horizontal press, made in 1989. The idea of these cage presses is that they are like horizontal basket presses. The two ends of the press squeeze the grapes and the juice escapes through holes in the cage. This is different to most modern presses, which have an inflatable bag that squeezes the grapes by inflating and deflating in cycles (known as pneumatic presses). The cage press is capable of excellent results, but you have to manage it manually for best results, and know what you are doing, stopping when the quality of the juice goes down.

As the grapes are pressed, the juice drips down into the tray, and is then pumped off to a tank for settling. It’s not protected from oxygen and so it turns a muddy brown colour. After pressing is finished, it’s time to remove the skins and clean the press ready for the next lot. This isn’t the most exciting job. It’s also time to wash the crates that the grapes came in, ready to send them out for another pick. I spent quite a bit of time doing this.

I also spent a lot of time sorting the Pinot Noir from the Cinema vineyard in Hemel-En-Aarde. This came in the previous day and had been kept overnight in a cold room. It’s always best to process grapes cold, and if they are picked in small crates then they can be kept for a day or two before processing with no loss in quality.

The sorting table is important for making top Pinot Noir. The dry growing season meant the fruit was very healthy, and we were looking for just two things as we sorted. The first was bird damage: the drought has left birds hungry, and when they peck at grapes the result can be damage that leads to sour rot developing. The second was raisining: the heat and warm winds can causes some berries to dehydrate, and they add sugar and slightly raisiny flavours to the must. We began by sorting for these raisins, but later any bunches with some raisining were put back into crates for processing on their own later.

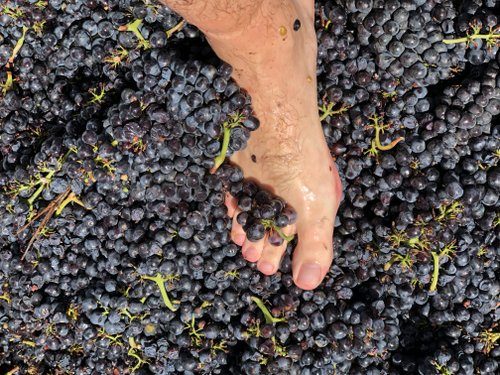

After the Pinot passed the sorting table, it was taken by conveyor to a plastic fermenting bin as whole clusters. This ferment will be 100% whole cluster. Other ferments in larger tanks are part whole cluster and part destemmed, with the destemmed portion pumped over the top of the whole bunches. In order to get the fermentation going, I foot trod the whole clusters in the plastic bin to release some juice and mush things around a bit. The grapes were cold, and the stems are a bit scratchy, so it’s not the most comfortable feeling. But it does give you a connection with the wine, doing something so physical.

There were a few other tasks, but processing the Chenin and the Pinot were the two main focuses. It’s quite physical work, and for me it was great to get a chance to look behind the scenes again (I’ve done bits of vintage elsewhere). I’m here for another 10 days, so it should be a great chance to learn more about how some of my favourite wines are made.

1 Comment on Winemaking at Gabrielskloof: pressing Chenin Blanc and sorting Pinot Noir

Pity you put that underpants shot on FB Shame on you denying your fans here 😉