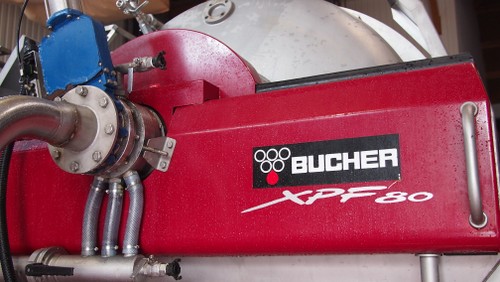

One of the things I saw in Provence was the way that many of the wineries are projecting the juice by pressing in the absence of oxygen. Pictured above is the press at Chateau Gassier, which has been fitted with the Bucher Inertys system.

The big bag (pictured below is one at Chateau Jas d’Esclans) contains nitrogen gas, and is flexible. It breathes in and out like a lung, depending on the pressing phase. As a result, a closed loop is created, where the gas in the system is nitrogen, not air, protecting the juice from any oxidation at all. Of course, you could just inject nitrogen into the press with every cycling, but then you’d use a lot of it, and the cost would be prohibitive. The creation of the closed loop is the key to the success of Inertys.

This is ideal for making high quality rose, where the protected juice keeps all its aromatic qualities, as well as preserving precursors of aroma compounds (which the yeasts use to make aroma compounds during fermentation) that might also be susceptible to oxidation. Grape must is capable of taking up considerably more oxygen than wine is. It means that it’s possible to use less sulfur dioxide during winemaking, too. Not only do you need to add less to the must, but also the oxidation inhibitor glutathione is protected, and this can have an important role to play later on in winemaking.

Another innovation used by some rose winemakers is shown above at Minuty. Hand-picked grapes are destemmed and then pumped into a device that cools them down before they go to the press. If you have to process a lot of grapes, it’s not always possible to leave them in a cool room overnight, and if you are picking by hand it isn’t always easy to pick at night, or very early in the morning.

Leave a Comment on Pressing under nitrogen, the Inertys system